- Date: 1999 – 2000.

- Developed by ASM Dimatec.

- Customers: Ford.

- Authors: Raúl Bartolomé Castro and other engineers.

- Contribution of Raúl: electrical designer. Creation of schematics in ePLAN, selection of electrical elements and creation of electrical documentation.

- Market: automotive subsidiary.

- Product category: industrial machinery.

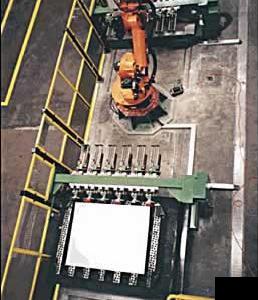

This system consisted of a press line and the sheet unstacking system. The de-stacking was implemented using a robot, which extracted the sheets from the pile and introduced them in the first press. The security criteria were very severe: Pilz security automatons and all wiring with an emergency mechanism. The project was selected to carry out an audit of the QS9000, which is an important quality criterion within the automotive sector. The qualification of the previous studies and electrical plans were excellent.

In the following illustrations you can see from left to right: the station where the sheets are located, the robot in charge of unstacking and the beginning of the press line. Four very similar versions of this machine were assembled at the Ford Valencia plant.